Features and Functionality of Drone Engine Test Bench

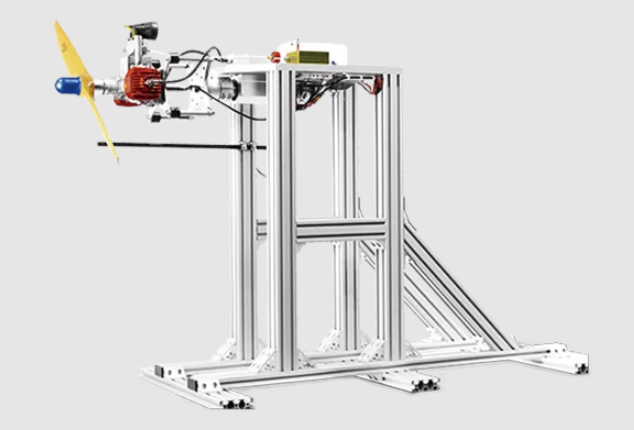

The Drone Engine Test Bench serves as a pivotal tool in the development, optimization, and assessment of drone propulsion systems. It is an intricate assembly of precision instrumentation, data acquisition systems, and safety measures, all orchestrated to provide a controlled environment for testing various engine configurations. This enables engineers and researchers to gain invaluable insights into the performance metrics, efficiency, and overall functionality of drone engines.

Key Features and Functionality

Our state-of-the-art Drone Engine Test Bench boasts an array of cutting-edge features that make it a cornerstone of UAV testing:

1. Realistic Simulations

The test bench replicates real-world flight conditions, allowing for a comprehensive evaluation of engine behavior during takeoff, flight, and landing. This level of realism enables engineers to identify potential issues and fine-tune engine parameters for optimal efficiency.

2. Data-Driven Analysis

Precise sensors and data acquisition systems collect a wealth of information during each test, including thrust output, fuel consumption, exhaust emissions, and more. This data-driven approach empowers engineers to make informed decisions regarding engine design and performance enhancements.

3. Customization Capabilities

Our test bench offers flexibility in accommodating a wide range of engine types and sizes. From small quadcopters to large-scale industrial drones, the test bench can be tailored to suit the specific requirements of each propulsion system.

4. Safety First

Safety is paramount in UAV testing. The test bench incorporates comprehensive safety protocols and containment measures, ensuring that tests are conducted without risk to personnel or the surrounding environment.

Advancing UAV Technology Through Testing

The significance of the Drone Engine Test Bench extends beyond mere assessment—it is a catalyst for technological breakthroughs and industry advancements. By providing engineers with a platform to iterate and refine engine designs, we contribute to the evolution of UAV technology in several crucial ways:

1. Performance Enhancement

Through rigorous testing and analysis, engineers can identify inefficiencies and areas of improvement within drone engines. This iterative process leads to enhanced performance, longer flight durations, and increased payload capacities, pushing the boundaries of aerial capabilities.

2. Reliability and Safety

Safety is non-negotiable in the aviation industry. The moter tester aids in identifying potential engine malfunctions or anomalies, enabling manufacturers to develop engines that are reliable, resilient, and capable of withstanding demanding operational conditions.

3. Environmental Responsibility

As environmental concerns rise, the aviation sector seeks to minimize its ecological footprint. The data acquired through the test bench assists in developing engines that are more fuel-efficient and emit fewer pollutants, aligning with global sustainability goals.

A Glimpse into the Future

The continuous evolution of drone technology holds promise for diverse applications, from surveillance and logistics to scientific research and entertainment. As the UAV landscape evolves, so too will the capabilities of the Drone Engine Test Bench. At WingFlying, we remain committed to pushing the boundaries of aeronautical testing, driving innovation, and shaping the future of UAVs.

Conclusion

In the dynamic realm of drone technology, the Drone Engine Test Bench stands as a beacon of progress and innovation. Its role in refining propulsion systems, enhancing performance, and ensuring safety cannot be overstated. As we navigate the skies of tomorrow, the invaluable insights gleaned from this advanced thrust stand apparatus will undoubtedly shape the trajectory of UAV development. Join us at the forefront of aeronautical advancement, where precision meets possibility.

评论

发表评论